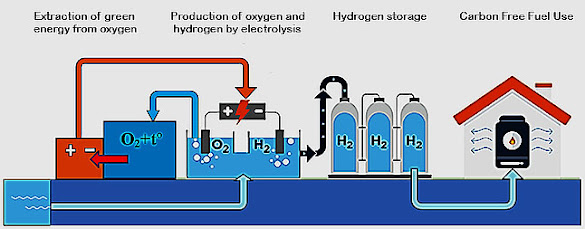

The

concept of producing cheap green hydrogen by electrolysis of water and with an

internal energy cycle.

Today,

two problems are very acute all over the world - cheap renewable green energy

and capturing CO2 from the Earth's atmosphere.

20

countries from different continents have already pledged to completely abandon

the use of coal for electricity generation. Italy is implementing such a plan

by 2025, and Finland by 2030. The Netherlands will close all coal-fired power

plants in the country by 2030, France by 2023 and the UK by 2025. Canada also

plans to be coal-free by 2030. In Germany alone, 84 coal-fired power plants

will be closed.

We

have already talked about the problem of capturing CO2 earlier. Ejecting 50

billion tons of CO2 into the Earth's atmosphere every year, it is ridiculous to

talk about projects that can ensure the absorption of CO2 from the atmosphere

in the amount of one hundred thousand tons or even a million tons. First, we

need to solve the problem of generating cheap green renewable energy that will stop

emitting CO2 into the atmosphere, and then we can talk about the mechanisms for

capturing it.

And

now we have come to the conclusion that today the governments of many countries

and many companies (mainly for budget money) are trying to solve the problem of

renewable green energy by producing green hydrogen obtained from water by

electrolysis. This is a very expensive way, associated with a large expenditure

of electricity, which is already sorely lacking in many regions of the world.

What

do they offer?

It

is proposed to combine green hydrogen production plants with sources of

renewable or simply cheap electricity - solar, wind or nuclear power plants.

But, the electrical energy generated by these sources is not as cheap as they

say. And the cost of green hydrogen produced in this way is very high,

including due to the huge consumption of electricity required for its

production.

The

most interesting thing about the production and use of hydrogen is the energy

balance of these processes. Let me explain what this means.

It

takes about 60 kWh of electricity to produce 1 kilogram of green hydrogen. At

the same time, the calorific value of hydrogen is only 33 kWh of energy. When

using this kilogram of hydrogen in fuel cells, the efficiency of which today

does not exceed 60%, the output can only be 20 kWh of electricity. And when

using this hydrogen in an atmospheric car engine, the efficiency of which is

30%, only 10 kWh of energy can be obtained at the output (besides, it will no

longer be green energy).

That

is, by spending 60 kWh of electricity to produce one kilogram of green

hydrogen, this hydrogen can produce either 20 kWh of clean electricity or 10

kWh of dirty energy.

The question arises - why then, in principle,

the production of green hydrogen is needed, if using lithium-ion batteries, the

efficiency of which is more than 90%, these 60 kWh of electricity can be

accumulated with a loss of only 6 kWh? Yes, and storing electricity in

batteries is simpler and safer than storing hydrogen.

We are told that by producing hydrogen it is

possible to store excess electricity produced by renewable energy sources. It

is also said that the cost of producing green hydrogen today is 6 US dollars.

Both of these statements are false.

First I want to dwell on this method of energy

storage. Tell me, which of you would like to earn 3,000 dollars a month by hard

work and give them to the bank in such a way that only 1,000 or even only 500

dollars are added to your account, and the rest disappear into thin air? So why

are you being convinced that the loss of energy in the production of hydrogen

is different?

Maybe you think that you are not being deceived

with the cost of producing green hydrogen, and that it really costs $6 per 1

kilogram today? Then count yourself. In the EU countries, you pay an average of

20 cents per 1 kWh of electricity (and do not say that there is cheap green

energy - the same deception reigns there). 60 kWh at 20 cents will already be

$12 per kilogram of hydrogen.

Add here the costs of transporting, storing,

charging hydrogen into fuel cells. Add to this the depreciation costs for

hydrogen production plants and fuel cells, and you will see that the real price

of green hydrogen today is 20-25 dollars per 1 kilogram. But what about other

countries, for example, Oceania, where the cost of 1 kWh of electricity can

exceed 50 cents? At what price will they have green hydrogen?

And if you are told that electricity with a

very low cost (up to 2 cents per 1 kWh) is spent on the production of green

hydrogen, then give up hydrogen altogether and let your government provide you

with electricity at 2 cents per 1 kWh. And you yourself will use it, heat up

and charge your electric vehicles. Do you think they will give you that

opportunity? No.

Have you ever wondered why your governments are

so eager to transform expensive green electricity into hydrogen, despite the

energy losses of this process of 65-85% and the huge costs associated with

this, which already amount to trillions of dollars around the world and will

only grow?

And if you consider that no government has its

own money, and all this is your money, then one gets the impression that in

this way your money, which is collected from you in the form of all kinds of

taxes, is transferred from your own pockets to other pockets. And you get

expensive electricity, expensive gas and very expensive hydrogen. Yes, some of

the costs of producing green hydrogen are covered by your governments, but this

is also your money.

But, is the technical problem of obtaining

cheap green hydrogen so hopeless? Is it possible to solve this problem so that

the production of green hydrogen becomes economically viable? Can. It is

necessary to reduce the consumption of electricity from external sources, where

it is quite expensive.

Now let's see how this can be done.

First of all, I want to explain that we offer

installations for the production of cheap green hydrogen only by combining them

with oxygen energy, as a result of which we refuse to use expensive energy from

external sources to operate the electrolyzer.

In the proposed version of the installation for

the production of electricity, oxygen is used, which is also produced in other

installations, but is released into the atmosphere.

That is, it is not correct to say that 60 kWh

of electricity is consumed to produce 1 kilogram of hydrogen in an

electrolyzer. These 60 kWh of electricity are used to produce 1 kilogram of

hydrogen and 8 kilograms of oxygen. At the same time, 33 kWh of energy can be

obtained from 8 kilograms of oxygen that are emitted into the atmosphere, and

the missing energy can be obtained from oxygen extracted from the atmosphere.

In both cases, the "fuel" for obtaining energy for the operation of

the electrolyzer is almost free.

Such a green hydrogen production plant is an

oxygen power plant combined with an electrolyzer of any type and manufacturer.

Why is such a plant for the production of green hydrogen better than other

existing developments?

The fact that this technology provides for the

production of hydrogen also by electrolysis, but due to the internal energy of

this process. Internal energy refers to the energy released from the process of

spontaneous ionization of oxygen, which is released from water simultaneously

with hydrogen. In conventional electrolyzers, oxygen is vented to the

atmosphere, but in the proposed project it is used to generate energy.

That is, this power generation mechanism is an

energy system built into the structure of the hydrogen production plant, which

uses the oxygen produced by the electrolyser to produce energy. And this energy

is spent on the operation of the electrolyzer itself. Thus, in the proposed

installation, an internal energy cycle is carried out. And the missing energy

is produced from atmospheric oxygen.

Scheme of hydrogen production with internal

energy turnover

The advantages of this setup are obvious:

1) It runs on its own electricity, the cost of

which will be up to 1 cent per 1 kWh. For the production of 1 kilogram of

hydrogen, such a plant will also consume 60 kWh of electricity, but the cost of

this electricity will be only 60 cents (an average of 20 times less than other

systems of this type existing or being developed).

2) Such an installation can operate and produce

hydrogen continuously at maximum capacity, and not at peaks in the production

of electricity from external sources dependent on the sun or wind.

3) Such an installation can produce hydrogen in

the place where its consumers are located, which makes it unnecessary to

transport and store it in large volumes - because it can always be produced

again.

4) When there is no need for hydrogen, such a

plant will be able to generate very cheap electricity from oxygen released from

the atmosphere.

5) The cost of hydrogen produced will be from

one to two dollars per kilogram, depending on what equipment (which companies)

will be used to create such a combined plant.

Today, the production of green hydrogen will be

cost-effective for the consumer even at a price of $4 per 1 kilogram. At this

price, its specific efficiency in fuel cells in transport will be higher than

that of gasoline and with absolute environmental cleanliness.

It can be explained like this.

One kilogram of hydrogen ($4), when used in the

fuel cells of a car, can generate at least 16 kWh of energy on the wheels of

this car.

Three kilograms of gasoline (not less than $

4), when used in a car engine, can generate no more than 15 kWh of energy on

the wheels of this car.

The gain from hydrogen is not big, but there

are other advantages of using it - environmental friendliness, no need for

exhaust gas catalysts, quiet operation, and much more.

And already at the cost of hydrogen at $2 per 1

kilogram (the average profitability of production is about 30%), the gain from

its use over gasoline today will be 2-2.5 times.

No existing green hydrogen production

technology in the world can come close to such indicators either now or in the

foreseeable future. At least 30-40 years old.

These are excellent economic results for

providing the whole world with clean energy and reducing carbon dioxide

emissions into the Earth's atmosphere by 85% in 20 years. And today this is the

only real way to save the climate and ecology of the Earth without harming the

activities of mankind.

P.S. Our company "ION-Energy-Saving Technologies" has been developing oxygen energy for more than ten years, and today we have already built and successfully tested a prototype oxygen processor that releases twice as much energy as it spends on its work. We are now actively looking for a financial partner-investor for the construction of a pilot project for an oxygen power plant.

Комментарии

Отправить комментарий